Toys

One of the primary industries we have assisted throughout the years is baby items. We are able to produce a wide variety of amazing plastic toy molds that will excite both parents and kids thanks to our injection molding and overmolding services.

Plastic Injection Molding Enterprise for Infant Goods

Babies are priceless blessings that everyone cherishes. For this reason, we at Krishna Enterprises take additional care when designing baby products and baby product molds. We are committed to making sure that every product is completely safe in terms of its construction, features, and material makeup. Regarding manufacturing, we also make sure that our molds work well throughout the production process and that the parts are designed to be manufactured.

Baby product plastic injection molding services

Design of Baby Products

Pediatric safety regulations serve as a guidance for our infant product designs. They consist of robust, lightweight structures that are simple to manage. Every design has soft, rounded edges to keep young children safe. We top it all off with vibrant colors and baby-friendly design ideas.

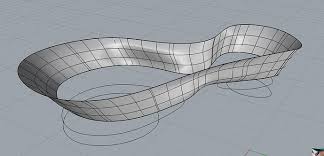

Design of Plastic Molds

Smooth finishes are necessary for plastic infant products, some of which, like toy molds, can have fairly intricate structures. Despite this, our design team has a lot of experience, and MoldFlow software evaluates mold designs, allowing us to make changes prior to prototyping and save money and time.

The 3D Printing Process

For small component production and prototyping, we provide 3D printing services. Our 3D printers generate parts with excellent resolution and provide a true-to-life image of the injection-molded component. In addition to being less expensive than injection molding when producing samples, it takes roughly three to five days to materialize a completed product.

CNC Machining

Computer systems are used in CNC machining to operate production tools. Due to their great accuracy and high tolerances, CNC machines are better suited for making big prototypes of infant items or their molds. Additionally, because of their material flexibility, we can use steel to make objects.

Making Molds

Our technology-driven equipment allows us to produce molds with extreme accuracy and tolerance. Because every step of the process is automated and closely supervised by our injection mold manufacturing engineers, there are fewer errors. Every mold goes through quality testing after production before being given the all-clear to be shipped.

Using Injection Molding

Our cost-effective injection molding services can provide high-quality injection molded baby products on demand with short lead times, making them perfect for firms who cannot manage production. We handle every step in-house, including chilling, surface finishing, and resin injection. This ensures that items are standardized in terms of quality.

The Purpose of Injection Molded Parts in the Baby Product Sector

Experience with Injection Molding

We have been manufacturing infant product molds for around ten years. We were able to hone our injection molding skills during those years. Additionally, we employ some of the top designers who will guarantee that every toy mold you create is of the highest caliber.

Personalized Resolution

We are fully aware that every single plastic toy mold ought to be as distinctive as feasible. which is why we provide our clients with bespoke solutions. You can have your molds made to your exact requirements with these alternatives.

Quality Assured

Being an established injection mold company, we double verify every product as part of our routine. We are able to guarantee only the highest quality items for our clients since we have an extremely strict quality control system in place.

Safe Materials for Infants

It is known that infants may inadvertently put items meant for babies in their mouths. We prioritize using only non-toxic materials in our toy molds because of this. Before we spend any money on molding supplies, we confirm again with our suppliers.