Product Design

Utilizing our plastic part design, you might communicate project specifics. Krishna Enterprises can accommodate any unique design you can dream of with this capability.

Expert Plastic Prototype Producers You Can Trust

Our top goal when producing injection molding products is to make sure that each one is as flawless as possible. Although we are aware that there isn’t a standard size for molds, we will still try our best to collaborate with you during the entire process, regardless of whether you send us a sample or only a 2D file. You should offer the most important information about your project first. We will quickly analyze your plastic molding design after we receive all the project specifics, and we’ll make any necessary adjustments thereafter.

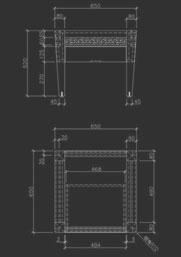

Examine Every Design Factor Associated With Injection Molding

Our professionals take the time to thoroughly examine important elements of your design before we begin the injection molding process. We examine the dimensions and size. This guarantees the utmost accuracy in your plastic moulding goods.

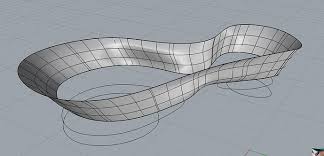

Evaluation of Plastic Components

Once we receive your initial feedback, we gather data to assess each design element’s viability.

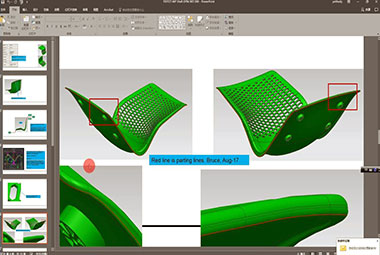

DFM

Design for Manufacturability is included into every step of the product development process to streamline production, cut expenses, and avoid costly delays.

Modifications to the Mold Design

Based on our experience, our designers may offer recommendations for material choice, wall thickness analysis, tooling, mold flow analysis, surface treatment, and component decorating.

Plastic Rapid Prototyping

Rapid 3D Printing

Quick and realistic peeks at your freshly produced product are made possible by fast prototyping, which is ideal for those who are eager to develop and test new product ideas. At your request, a rapid 3D prototyping service can be provided.