Injection Molding Parts

Krishna Enterprises specialize in making plastic injection molding parts that are useful in several industries like automobile, electronics, and home appliances.

Create and Make the Required Plastic Injection Molding Parts

Krishna Enterprises is an expert and top producer of injection-molded parts. We are a one-stop shop with a variety of services to meet all your demands for plastic injection parts.

Utilizing cutting-edge injection molding technology, our engineers run a lean operation and handle every aspect of production internally. We employ expert analysis and stringent quality control procedures from designs to delivery to ensure the creation of high-quality plastic mold parts.

Services for Components of Plastic Injection Molds

Particular Plastic Components

With years of experience and a state-of-the-art production base, we create eye-catching designs to meet your needs for custom plastic parts. After properly evaluating your prototype and samples, we will create distinctive product designs that meet your needs, including the specific size, shape, and color that you request.

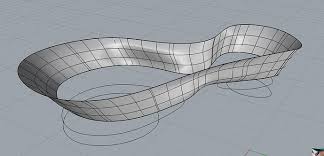

Design of Plastic Parts Mold

Our engineers’ proficiency makes it easy to create mold designs that are effective. We will create the ideal mold to represent your unique plastic components. Following receipt of your sample, our professionals will optimize your mold design in accordance with your specifications and perform a DFM analysis report.

3D Printing

High-definition prototypes are produced quickly and more accurately with the aid of 3D printers. Among the many advantages of our cutting-edge 3D printers is the ability to produce intricate sample designs at reasonable costs. It also makes it possible to view designs and make quick adjustments to them.

CNC / VMC Machining

We use CNC machining, a manufacturing technique that uses computerized control to increase injection molded part production. By doing this, we can promptly and satisfactorily address your needs for plastic injection parts. It’s a special kind of production that makes flawless and quick copies of plastic components.

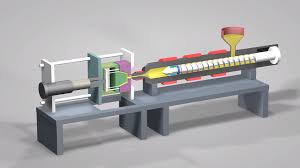

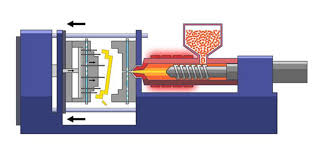

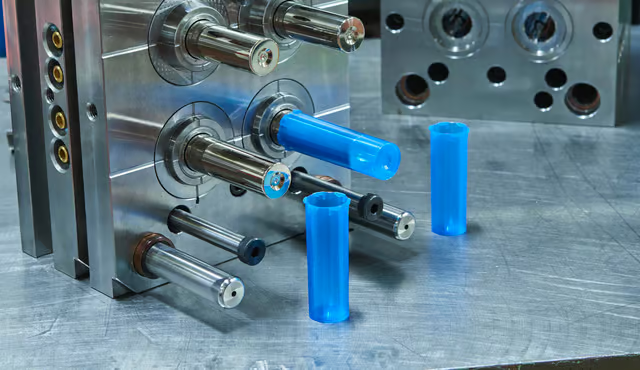

Manufacturing of Injection Molds

With the ability to swiftly make thousands of injection mold components, Krishna Enterprises offers the best injection mold-making services. When creating molds, we use both our experience and knowledge and high-quality steel. This facilitates quickly completing orders for large injection molding parts.

Produce Injection Mold Parts

Producing plastic parts in large quantities is incredibly simple when we combine our state-of-the-art injection molding technology with our highly accurate produced molds. Our engineers will quickly get to work producing highly useful injection-molded plastic components.

Why Injection Molding Is Useful in the Plastics Sector

Quick Prototyping

Because 3D printing and CNC machining technologies enable quick prototyping, injection molding production times are shortened. You can also receive prompt feedback on the feasibility of your designs thanks to this.

Excellent Cost-Effectiveness

Because they are constructed of sturdy steel, injection molds are incredibly practical and long-lasting. They are designed to produce thousands of plastic pieces with little financial outlay.

Reliability in scale

The quality and functionality of the plastic injection molded parts may be maintained while increasing the manufacturing scale thanks to injection molding assistance.

Control of Quality

From the design phase through the injection molding stage, there are multiple checks during the manufacturing process. Strict quality policies are implemented and followed when conducting any of these procedures.