FAQ

Let Us understand the landscape of machining and tooling manufacturers in India.

What types of machining and tooling services are commonly offered by manufacturers in India?

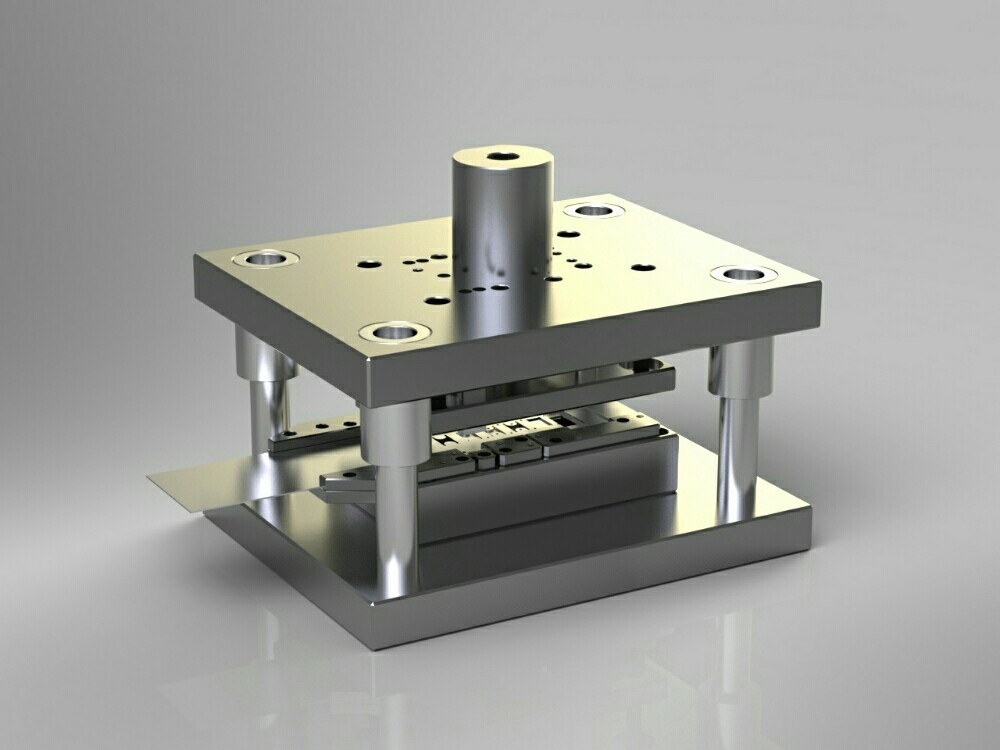

Manufacturers in India typically offer a range of services including CNC machining, milling, turning, grinding, drilling, and precision tooling. They may also provide custom tooling, prototyping, and mass production services.

How do I choose the right machining and tooling manufacturer in India?

When selecting a manufacturer, consider factors such as the company’s experience, certifications (like ISO), capabilities, quality standards, delivery timelines, and customer reviews. It’s also important to evaluate their expertise in your specific industry.

What certifications should a reputable machining and tooling company in India have?

Reputable companies usually hold certifications like ISO 9001 (Quality Management System), ISO 14001 (Environmental Management), and ISO/TS 16949 (for automotive industry standards). Other specific certifications may be required depending on the industry.

Can Indian machining and tooling manufacturers meet international quality standards?

Yes, many Indian manufacturers adhere to international quality standards and export their products globally. They often have state-of-the-art facilities and skilled professionals to meet stringent quality requirements.

What materials can Indian machining companies work with?

Indian machining companies work with a wide range of materials including metals (aluminium, steel, brass, copper), plastics, composites, and exotic materials like titanium and Inconel. Their capabilities usually cover both standard and specialized materials.

What is the lead time for machining and tooling orders in India?

Lead times can vary depending on the complexity and size of the order, but typically range from a few days to several weeks. For custom or large-scale projects, it’s advisable to discuss timelines directly with the manufacturer.

Do Indian machining and tooling companies provide design and engineering support?

Many companies offer design and engineering support, including CAD/CAM services, to help optimize product design for manufacturability and cost efficiency. This can be particularly beneficial for prototyping and custom projects.

What are the typical payment terms and conditions with Indian manufacturers?

Payment terms vary but often include options like advance payment, Letter of Credit (LC), or payment upon delivery. It’s important to clarify terms upfront, including currency, payment methods, and any applicable taxes or duties.

How do Indian machining and tooling companies handle shipping and logistics?

Companies usually offer a range of shipping options, including domestic and international logistics services. They work with reputed logistics partners to ensure timely delivery and may also provide packaging, labelling, and customs documentation support.

Are there any language barriers when dealing with Indian machining and tooling manufacturers?

Most manufacturers have English-speaking staff, especially in export-oriented companies. Communication is generally smooth, but it’s helpful to provide clear, detailed specifications and confirm all requirements in writing to avoid misunderstandings.