Kitchenwares

You will receive a number of services related to plastic home products when you collaborate with Krishna Enterprises. By putting cutting-edge injection molding techniques into practice, we support your company’s growth in plastic home goods.

Injection molding and mold manufacturing for plastic kitchenware product

Krishna Enterprises is a prominent producer of plastic home goods and a one-stop shop for all things related to plastic kitchenware products.

We design and produce molds and injection molded kitchenware plastic products under one roof utilizing injection molding technology in accordance with your specifications. Our designs are distinctive and very functional, and they are dependable and creative.

Plastic Injection Molding Services for Kitchenware's

Design of Plastic Kitchenware

By fusing our exceptional creativity with efficient methods, we create the ideal solution to meet your needs. We can fully customize the size, form, and color of your kitchenware plastic products thanks to our broad product design capabilities.

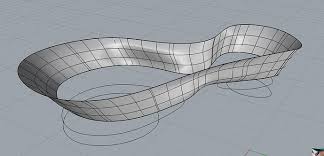

Mold Design for Kitchenware

With a sophisticated specialty in mold creation, we create the ideal mold to form your plastic kitchenware products. No matter how complicated and detailed the designs are, we deliver you a mold design that meets your objectives by using straightforward procedures.

The 3D Printing Process

We can quickly and affordably create high-definition prototypes with 3D printing. This significantly shortens the turnaround time required to complete the production of complex parts. However, because our 3D printing application offers great precision and reliable repeatability, quality is not compromised.

CNC Machining

We assist with injection molding home goods by using CNC machining to remove layers of material from an already-existing component. High scalability, personalized finishes, and speedy turnaround are supported by this kind of manufacturing.

Making Plastic Molds

At Krishna Enterprises, we understand that quality plastic molds are essential since they set the tone for the injection molding procedure. As a result, we give great attention to the mold-making process to guarantee excellence in every way.

Injection Molding of Plastic Kitchenware Items

We provide a wide range of injection molding services, including the manufacturing of large quantities of plastic home goods. Additionally, we have experience working with hundreds of resins, which enables us to offer a range of solutions to meet the needs of our clients.

Why the Plastic Kitchenware's Industry Uses Injection Molding

Quick Prototyping

Prototyping takes less time when 3D printers and CNC machining are used in the injection process. This reduces the amount of time needed to develop part designs. It also enables you to quickly receive feedback on how feasible your designs are.

Efficient Cost Management

Injection molds are built to be extremely functional, robust, and long-lasting. A mold can be utilized for thousands of parts production without incurring additional costs over an extended period of time, all while preserving product quality.

Reliability in scale

Increased production volume can be achieved with injection molding without compromising the manufacturing process’s quality or functionality. It is a versatile production technique that facilitates the creation of various plastic components.

Control of Quality

We ensure a superb quality output by carrying out several testing and inspections. Experts who enforce stringent quality norms supervise the execution of each of these steps.