Home Appliances

Krishna Enterprises has assisted numerous businesses with their home appliance mold problems over the last ten years. In order to bring your ideas for household appliances to life, we offer overmolding molds in addition to insert injection molding services.

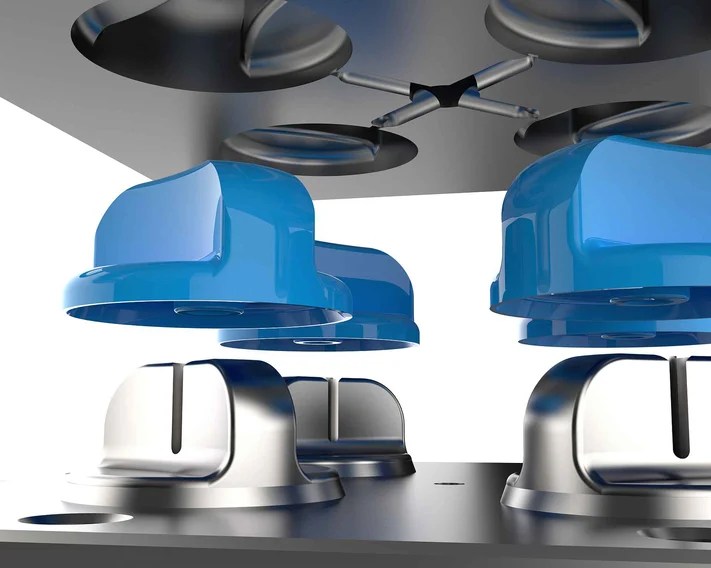

Injection Molding of Plastic for Domestic Appliances

Appliances are a necessary component of every home. For cooking, personal grooming, entertainment, and a host of other crucial uses, consumers depend on them. At Krishna Enterprises, we are experts in offering injection molding services to companies who produce these crucial goods. Our goal is to provide designs and plastic household appliance products that are both enjoyable to use and can be manufactured.

Our Home Appliance Injection Molding Services

Design of Plastic Products

Following the suggested safety guidelines for plastic household appliances, we strive for affordable, contemporary, lightweight designs. We operate within the design preferences of our clients and provide product design services at reasonable prices.

Design of Plastic Molds

The design team at Krishna Enterprises has experience creating molds for various household appliances using versatile design tools that allows for high accuracy design procedures. MoldFlow technology is used by a team of experts to examine each design and help fix any mistakes in mold functionality and design.

3D Modeling

Krishna Enterprises employs 3D technology for prototyping and offers its clients 3D services. Our team is able to test for functioning and design viability thanks to the high-quality samples that are produced quickly by our high-resolution 3D printers. Multiple prototypes can be produced simultaneously in as little as three to five days.

CNC Machining

Power tools with computer control that can create pieces out of metal, thermoset, and thermoplastic materials are called CNC machines. They are excellent for large household appliance prototypes or forging molds. Although the machining technique may retain tolerances of up to +/- 0.002mm, it takes roughly ten days.

Manufacturing of Injection Molds

Expensive high-precision gear is used to create molds that precisely mimic the plastic components of household appliances. Strict quality control measures and the guidance of knowledgeable molding experts are in place during our mold-making procedures. To weed out defects and inefficiencies, technology-based quality inspections come after production.

Using Injection Molding

Appliance injection molding services are provided by certified vendor Krishna Entrprises. We have streamlined our injection molding procedures to cut down on cycle times and production expenses. Furthermore, we employ premium products from approved vendors. They don’t deform or develop cracks when put through injection molding procedures.

Why Injection Molded Plastic Components Are Used in the Home Appliance Sector

Experience with Injection Molds

For more than ten years, Krishna Enterprises has assisted home appliance manufacturers with their plastic injection mold requirements. We are more than capable of assisting both new and existing clients with their plastic mold designs, as we have honed our injection molding procedure.

Single-point of contact services

One of the best things about Immould is that we provide a whole suite of services, from designing appliances for your house to producing plastic parts for injection molds. You’ll have all you need to make your plastic molds if you register with us.

Competitive Cost

We are aware of the potential costs associated with mass producing your goods. One of Krishna Enterprise’s biggest benefits is this. We are more than capable of providing very fair and competitive costs for top quality products because of our extremely simplified approach.

Current Molds

We have a large collection of pre-existing molds because of our years of experience creating plastic molds. This implies that we have access to a large range of historical molds from which we could learn and identify common design blunders.