Medical Equipments

Plastic components and gadgets for medical use are made via a manufacturing method called medical injection molding. In order to generate a precise shape, it entails melting pellets of plastic resin and inserting the molten material into a mold.

Medical Equipments Injection Molding Company

One of Krishna Enterprises’ primary technologies, medical injection molding offers a state-of-the-art response to the manufacturing requirements of healthcare organizations that make medical molded products. As a producer of insert molding, we support device makers who come to us with ideas for new products and request that we mold components for testing in clinical settings and market analyses.

Plastic Injection Molding Services for Medical Equipment

Personalized Medical Equipment Add-Ons

With the latest equipment and more than ten years of experience, our engineers can create captivating product ideas. Based on an accurate evaluation of your samples and requirements, we will create distinctive designs to meet your specific needs for medical equipment molding

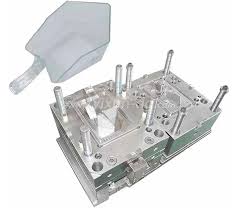

Medical Equipment Mold Design

With the skill of our qualified staff, we will create the ideal mold design with ease for producing your medical equipment molding. To make sure that your criteria are being met, our engineers will perform a DFM analysis report.

3D Printing

Using 3D printers, we can produce samples and meet your demands for medical equipment molding parts more quickly. Outstanding advantages of our 3D printing technology include the speedy and reasonably priced production of intricate part designs.

CNC / VMC Machining

We use computer numerical controlled (CNC) machining, a state-of-the-art manufacturing technique that improves the yield of medical equipment molding components. Your medical equipment molding parts samples may be precisely duplicated with this technique. In order to maximize quality in injection molding, this special technology is employed.

Injection Mould Making

Utilizing an injection molding manufacturing process, medical equipment molding accessory demands are promptly met. With more than ten years of injection mold production experience, you’ll gain from our depth of knowledge. We design molds that precisely make your plastic medical equipment molding components, making them excellent and very effective.

Manufacture Medical Equipment Molding

Producing solar panel parts is incredibly simple thanks to our superior injection molding technology, highly precise made mold, and outstanding product design. Our top-notch engineers will quickly get to work, producing the product in accordance with your requirements.

Why the Plastic Medical Equipment Industry Uses Injection Molding

Quick Prototyping

Fast prototype before injection molding is made possible by the use of CNC machining, 3D printing, and other technologies. Because errors are readily identified and corrected, accuracy is guaranteed.

Excellent Cost-Effectiveness

Since high-quality steel is used in their construction, injection molds are robust and useful. They are designed to swiftly and accurately generate thousands of plastic panel components at a minimal cost.

Reliability in scale

The increase of the production scale is supported by this manufacturing system. Because of its adaptability, it may be used to change production processes without compromising the quality of the plastic medical equipment molding components.

Control of Quality

Several quality requirements are followed during the injection molding procedures. Furthermore, a range of tests and inspections are carried out to validate the functionality of the medical equipment molding components.